Microfluidic Applications in Food Processing: Innovations and Future Directions

Section one

Microfluidic Application for Microencapsulation

The GIBMEC Liposomal machine effectively uses microfluidic technology to produce microencapsulation products. The technology of microfluidics is multidisciplinary and has a wide range of applications, one of which is in the food processing industry. In order to create food that is both more useful and safer, more modern technologies in food processing are required to meet the needs of the world’s continuously expanding population.

Microfluidic devices are a common option for this kind of processing. On the other hand, the method of microencapsulation involves surrounding minute particles or droplets with a coating to create tiny capsules with practical features. Typically, it is used to include small amounts of dietary items, enzymes, cells, or other materials. Here is the ultimate guide on microfluidic application for microencapsulation.

Microfluidics Techniques to Design Encapsulated Ingredients

In order to create innovative food microstructures for the quality, health, and pleasure markets, unit operations where the forming device’s scale is closer to the size of the structural components (i.e., 1–100 µm) will likely be necessary. Encapsulation is one specific method for ensuring the bioavailability of nutritional supplements or controlled release of active ingredients. The packing of tiny solid, liquid, or gas particles—also known as the core—within a secondary substance—also known as the shell or coating—to create tiny capsules is called encapsulation.

Application of Microfluidic Technology in Food Processing

An essential step in preventing food contamination and supervision is food safety analysis. The construction of efficient on-site, quick, precise, and well-liked food safety sensing techniques is urgently required. Microfluidic application for microencapsulation in food processing stands out among them for its distinct benefits in detection, such as reduced sample consumption, quick detection, easy operation, multi-functional integration, compact size, multiplex detection, and mobility. Here are some benefits of microfluidic application for microencapsulation products in the food industry:

- Solids, liquids, and gases may all be contained inside microencapsulates. This makes it easier to manage elements in the liquid and gas phases as solids.

- Numerous methods may be used to accomplish microencapsulation, each with a different goal in mind.

- It is possible to microencapsulate substances with the goal of keeping the core substance contained inside the capsule walls for a certain amount of time.

- Instead, core materials may be encapsulated such that the core material will either be released gradually via the capsule walls (known as controlled release or diffusion) or when external factors cause the capsule walls to rupture, melt, or disintegrate.

Droplet Microfluidics for Food and Nutrition Applications

Droplet microfluidic systems may be incorporated into lab-on-chip platforms for in situ and time-resolved studies, giving users unparalleled control over their production and attributes. On-chip studies of droplet interfacial characteristics, droplet-droplet coalescence, phase behavior of biopolymer mixtures, and reaction kinetics linked to food digestion and nutrient absorption are examples of how to use droplet microfluidics for food and nutrition.

Expanding Microfluidic Applications in Food Processing: Innovations and Future Directions

The integration of microfluidic technology into food processing represents a transformative shift, enabling precise control over microencapsulation processes. The GIBMEC Liposomal Machine exemplifies this innovation, utilizing advanced microfluidic systems to produce encapsulated ingredients with unparalleled accuracy. This article delves into the principles, applications, and future potential of microfluidics in the food industry, exploring its role in enhancing safety, nutrition, and sustainability.

Section two

Introduction to Microfluidics: Principles and Evolution

Microfluidics involves the manipulation of fluids at the microscale, typically within channels measuring tens to hundreds of micrometers. Originating in the 1980s from advancements in semiconductor manufacturing and lab-on-a-chip (LOC) technologies, microfluidics has evolved into a cornerstone of modern engineering. Its ability to handle minute fluid volumes with high precision makes it ideal for applications requiring controlled mixing, reaction, or encapsulation. Unlike traditional methods, microfluidic systems operate with laminar flow, allowing predictable fluid behavior and minimizing turbulence. This precision is critical in processes like droplet formation, where uniformity in size and composition is paramount.

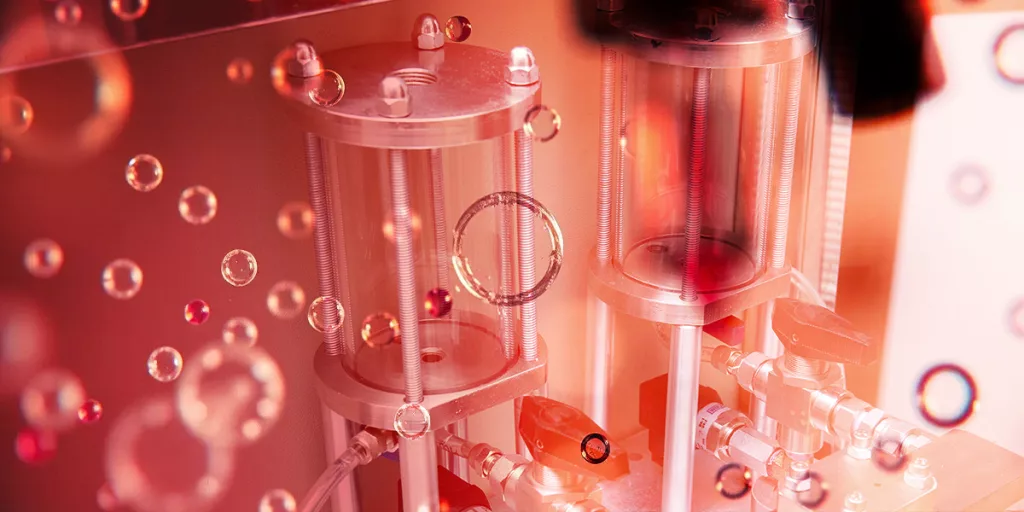

The GIBMEC Liposomal Machine: Design and Functionality

The GIBMEC Liposomal Machine leverages microfluidic channels to create liposomes—spherical vesicles with lipid bilayers that encapsulate bioactive compounds. Key components include a microfluidic chip with precisely etched channels, pumps for controlled fluid delivery, and sensors to monitor droplet size and shell thickness. The process begins with two immiscible fluids: one containing the core material (e.g., vitamins, enzymes) and the other the shell material (e.g., phospholipids). As these fluids intersect within the chip, shear forces generate uniform droplets, which self-assemble into liposomes. This method ensures consistent particle size (50–500 nm), enhancing stability and bioavailability compared to bulk techniques.

Microencapsulation Techniques: Beyond Traditional Methods

Traditional encapsulation methods, such as spray drying and coacervation, often result in uneven coatings and thermal degradation of sensitive compounds. In contrast, microfluidics offers several advantages:

- Precision: Tailored control over capsule size and wall thickness enables customized release profiles.

- Efficiency: Reduced waste through exact material usage and higher yield rates.

- Versatility: Compatible with diverse materials, including heat-sensitive probiotics and volatile flavors.

For instance, in spray drying, high temperatures can denature proteins, whereas microfluidic encapsulation occurs at ambient conditions, preserving bioactivity. Similarly, coacervation relies on pH adjustments, which may alter ingredient functionality, while microfluidics avoids such chemical interventions.

Applications in the Food Industry: Enhancing Nutrition and Safety

Microencapsulation addresses critical challenges in food production:

- Nutrient Fortification: Iron and vitamin D are encapsulated to prevent oxidation and mask undesirable tastes in fortified cereals.

- Probiotic Protection: Live cultures are shielded from gastric acids, ensuring viability until they reach the gut.

- Flavor Retention: Essential oils in beverages are encapsulated to prevent evaporation, maintaining aroma over shelf life.

In food safety, microfluidic sensors integrated into packaging detect pathogens like Salmonella through antigen-antibody interactions. These sensors provide real-time data via colorimetric changes, enabling rapid contamination checks without laboratory equipment.

Droplet Microfluidics: Advancing Nutritional Studies

Droplet-based systems compartmentalize reactions into picoliter volumes, facilitating high-throughput screening. For example, researchers simulate digestive processes by encapsulating enzymes and nutrients in droplets, observing breakdown kinetics under varying pH conditions. This approach has revealed insights into lipid digestion rates, informing the design of low-calorie fats that mimic traditional textures. Additionally, droplet platforms assess interactions between dietary components, such as how polyphenols bind to proteins, altering nutrient absorption.

Cross-Industry Applications and Sustainability

Beyond food, microfluidic encapsulation is revolutionizing sectors:

- Pharmaceuticals: Targeted drug delivery systems release chemotherapy agents at tumor sites, minimizing systemic toxicity.

- Cosmetics: Hyaluronic acid is encapsulated in moisturizers for sustained skin hydration.

- Agriculture: Pesticides are coated to degrade under specific environmental conditions, reducing runoff.

Environmentally, microfluidics reduces solvent use by 90% compared to conventional methods. Biodegradable shell materials, such as chitosan and alginate, further enhance sustainability, aligning with circular economy goals.

Challenges and Economic Considerations

Despite its promise, microfluidic adoption faces hurdles:

- Scalability: Transitioning from lab-scale to industrial production requires modular systems that maintain precision at high throughput.

- Cost: Initial investments in microfabrication equipment are substantial, though offset by long-term savings in material costs.

- Expertise: Operators require interdisciplinary training in fluid dynamics and bioengineering.

Companies like Nestlé and PepsiCo are piloting hybrid systems that combine microfluidics with existing infrastructure, balancing innovation with feasibility.

Future Directions: Smart Packaging and Personalized Nutrition

Emerging trends include:

- Smart Labels: Microfluidic sensors embedded in packaging monitor freshness, changing color when spoilage compounds are detected.

- AI Integration: Machine learning algorithms optimize encapsulation parameters in real-time, adapting to ingredient variability.

- Personalized Foods: On-demand encapsulation devices tailor nutrient ratios based on individual dietary needs, ushering in a new era of customized nutrition.

Read more about “Lab on a chip market | Its size and future growth in Europe“

Read more about “Fabrication and Applications of Microfluidic Devices: A Review”

Conclusion

GIBMEC is a made-to-order microfluidics company specializing in high-efficiency encapsulation solutions. Make-to-order Liposomal, ORDER NOW. Microfluidic technology, epitomized by the GIBMEC Liposomal Machine, is reshaping food processing through precise, sustainable encapsulation solutions. By overcoming traditional limitations and enabling novel applications, it holds the key to safer, healthier, and more efficient food systems. As research bridges scalability gaps and reduces costs, microfluidics will undoubtedly become a staple in global food innovation, transcending industries and driving progress toward a sustainable future.