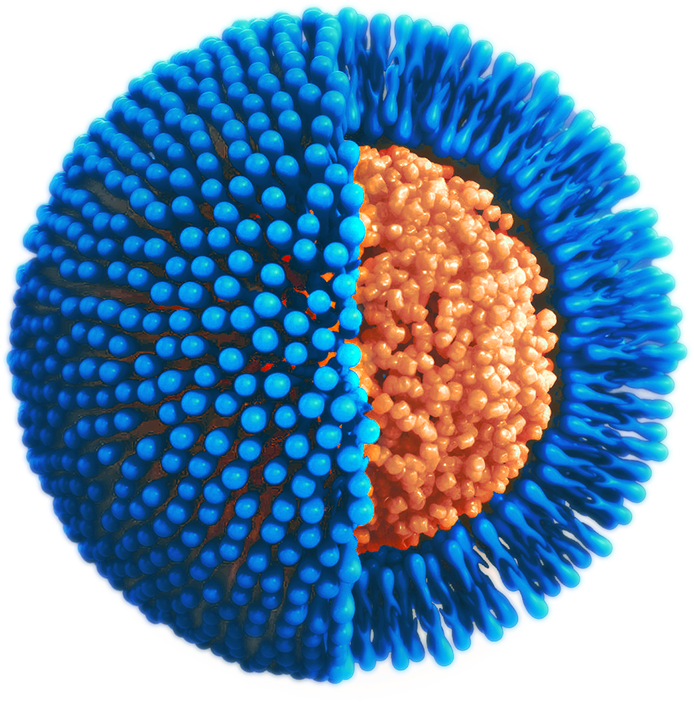

Liposome Production via Microfluidics

GIBMEC specializes in the production of premium-quality liposomes using advanced microfluidic technology. We offer fully customizable solutions, producing a wide range of liposomes tailored to meet specific requirements based on customer datasheets. Our precise and efficient microfluidic engineering ensures exceptional consistency and performance, enabling us to cater to all areas of liposome applications without limitations. With a global service reach, GIBMEC is committed to providing innovative, reliable, and scalable solutions to researchers, businesses, and investors worldwide.

Free consultation

About Microfluidics

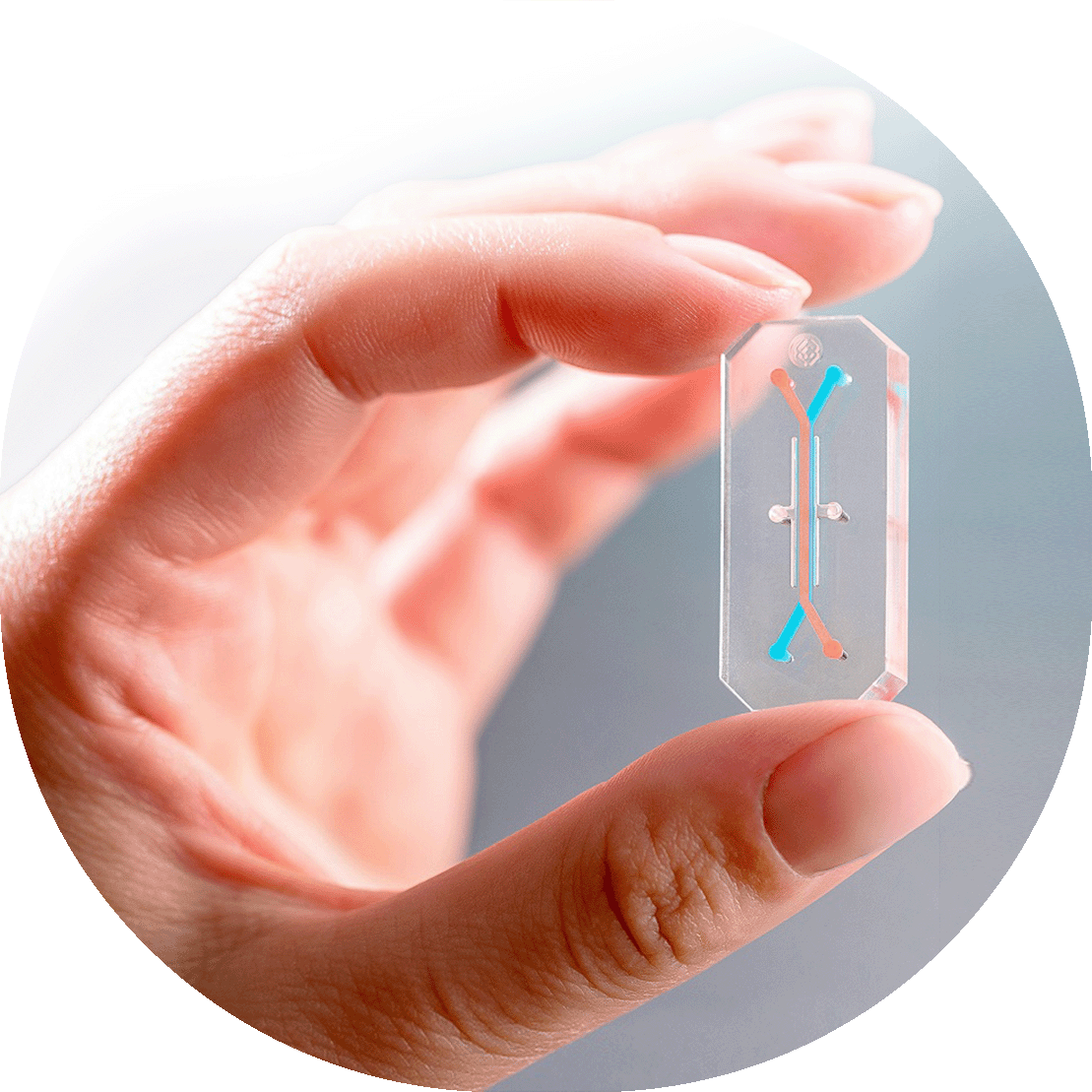

What is microfluidics?

Microfluidics is a term used to describe a class of techniques that are used to create fluid flows at extremely small scales, to the scale of the nanometer. This may be achieved by creating networks of microchannels within a substrate and using electrokinetic flows to transport samples through the channels. Microfluidics also encompasses lab-on-a-chip systems (which are also extremely miniature) and micromachined components. Microfluidics is a vital technology to develop for future point-of-care, patient, and lab-on-a-chip devices. The application of microfluidics in point-of-care devices will include, amongst other things, the development of inexpensive devices which can automatically analyze a range of important fluids, such as saliva and blood, from the environment. Such microfluidic devices could form the basis of tests that would enable doctors and nurses

Gibmec Services and Products

What do we offer at GIBMEC ?

OUR SERVICES

01.

Micrifluidic chip

Our chips are available for various pharmaceutical, food, cosmetic, and laboratory industries.

01.

High-pressure homogenizer

Our high-pressure homogenizer technology supports your product growth in production lines.

02.

Designing micrifluidic chip

We have the knowledge and technology to design and manufacture microfluidic chips.

03.

lithographic services

We provide lithography engineering services for microfluidics and other technologies.

OUR PRODUCTS

01.

Make to Order Liposome

Custom manufacturing solutions for liposomal delivery systems, ensuring precision and quality in tailored liposome production.

01.

Liposomal Vitamin D

Advanced liposomal technology for enhanced vitamin D absorption, offering maximum efficacy and health benefits.

02.

Liposomal Vitamin C

High-quality liposomal vitamin C supplements designed for superior absorption and powerful immune support.

03.

Ferrous sulfate liposome

Efficient liposomal iron supplements for improved iron absorption, supporting energy and overall health.

Cosmetic Industry

Food Industry

Drug Application

Agriculture

Gibmec

what industries used microfluidics?

Microfluidics is a fast-growing technology that combines microelectronics, chemistry, optics, and biology to make miniaturized systems for manipulating liquid solutions, including cells and chemicals, on a microscopic scale. It’s already found applications in fields such as medical diagnostics, biology, chemical, food science, and water and wastewater treatment and ect. Microfluidics is now in the stages of its commercialization as a technology platform for new products and applications.

- Gibmec has been able to develop and provide products that meet the needs of various industries, including food, medicine, agriculture, cosmetics, etc.

Covid-19 Prevention

Take steps to protect yourself

Nec habitasse sociis urna urna dignissim et ac parturient sed mi ultricies porttitor ligula eu elementum arcu leo, cum tellus suspendisse dignissim habitant pellentesque.

Stay at home

Nisl, dictum eros lectus fringilla enim quis et malesuada hendrerit arcu, mauris massa penatibus augue sed.

Cover caugh & sneezes

Varius urna ac pulvinar egestas libero tellus, nam amet, mattis lectus ullamcorper nunc elementum id quisque.

Wear a facemask

Sodales magna nisl pellentesque accumsan ut massa sed volutpat tellus tristique pulvinar nisi, eget sed purus.

Clean & disinfectant

Ut aliquet nunc, varius sed leo at pharetra, senectus et semper velit semper nam sed suspendisse.